Falcon RigwerX LLC

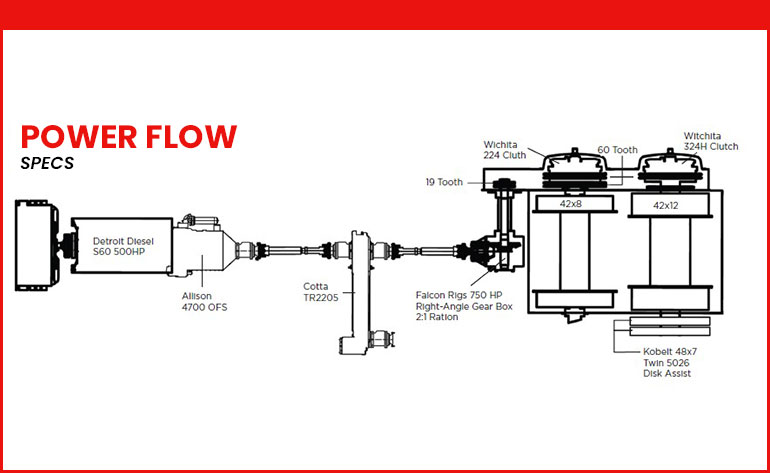

Hardened overlaid demountable steel brake rims are 42in diameter x 12in wide. Drum shaft diameter is 6.5in. 1in wire line size standard.

Hardened overlaid demountable steel brake rims are 42in diameter x 8in wide. Wire line capacity is 16,500ft of 9/16.

Draw Works Model 550/42x12, 42x8

(Double Tubing, Triple Rods)-(per API 4F)